Establishing a steel door seals factory involves a comprehensive process encompassing various stages, from initial planning and construction to production, quality control, and distribution. Here is an extensive description of what such a factory might entail:

Factory Design and Layout:

- The factory design is a critical initial step. It should be strategically located for easy access to transportation and suppliers of raw materials.

- The layout must be optimized for efficiency, taking into account the flow of materials, personnel, and machinery.

- Segregated areas are designated for different processes such as material storage, cutting and shaping, molding, quality control, packaging, and administration.

Raw Material Sourcing:

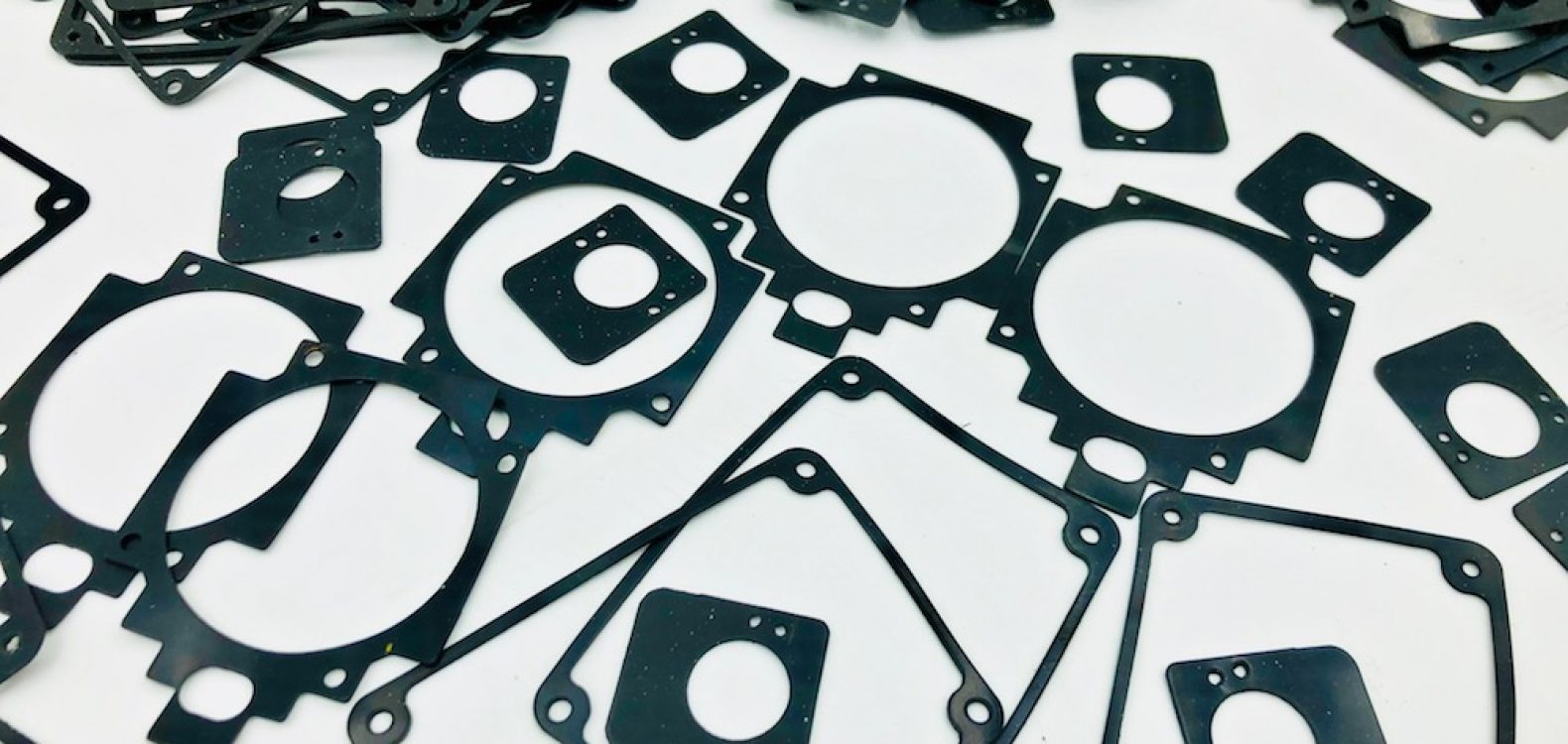

- Steel door seals are typically made from materials like rubber, neoprene, EPDM, or silicone, depending on the specific product requirements.

- Raw materials are sourced from reputable suppliers who provide materials conforming to industry standards.

- Material storage facilities are equipped to protect against environmental factors that could degrade the raw materials.

Manufacturing Equipment:

- The factory is equipped with specialized machinery for various production processes.

- Extrusion machines are used for shaping and molding rubber or other materials into the desired profiles.

- Cutting, slicing, and vulcanization equipment ensure precise sizing and durability of the seals.

- Injection molding machines may be used for certain seal designs.

- Quality control equipment, such as laser measurement tools, is integrated into the production line.

Production Process:

- The production process begins with the preparation of raw materials, which are mixed and formed into the desired shape.

- Continuous or batch processes are used, depending on the type of seal being manufactured.

- Vulcanization, a crucial step, involves subjecting the seals to heat and pressure to enhance their durability and resilience.

- Quality checks are conducted at various stages of production to ensure adherence to specifications.

Quality Control:

- Quality control is integral to the manufacturing process.

- Random samples are regularly tested for physical properties such as tensile strength, elongation, and hardness.

- Dimensional accuracy is meticulously monitored to ensure consistency.

- Seals are also subjected to tests for weather resistance, temperature tolerance, and chemical resistance.

- Defective products are identified and addressed promptly to maintain product quality.

Packaging and Shipping:

- Once the steel door seals are manufactured and quality-checked, they are packaged securely to prevent damage during transit.

- Packaging materials are selected to protect the seals from environmental factors and ensure they reach customers in pristine condition.

- Products are labeled with specifications, barcodes, and batch numbers for traceability.

- Efficient logistics and distribution systems are established to deliver products to customers locally and internationally.

Compliance and Certification:

- The factory complies with all relevant industry standards and regulations, including those related to environmental sustainability and workplace safety.

- Certifications from recognized bodies may be obtained to validate the quality and safety of the seals.

Research and Development:

- Ongoing research and development efforts are integral to product improvement and innovation.

- The factory may have a dedicated R&D department focused on developing new seal designs, materials, and production methods.

Environmental Considerations:

- Sustainability is a growing concern, and the factory may implement eco-friendly practices, such as recycling, waste reduction, and energy-efficient manufacturing processes.

Skilled Workforce:

- The factory employs a skilled and trained workforce, including technicians, engineers, quality control personnel, and administrative staff.

- Training programs and safety protocols are in place to ensure the well-being of employees.

Market Expansion:

- The factory may explore opportunities for expanding its product range to include seals for various applications, such as automotive, industrial machinery, and construction.

Customer Support:

- A customer support team is available to assist clients with inquiries, orders, and technical information.

- The factory maintains open channels of communication to address customer feedback and concerns.

In summary, a steel door seals factory is a complex operation that requires careful planning, state-of-the-art equipment, stringent quality control, and a commitment to producing high-quality, durable products. Such a facility plays a vital role in providing essential components for the construction and maintenance of secure and weather-resistant steel doors used in residential, commercial, and industrial settings.