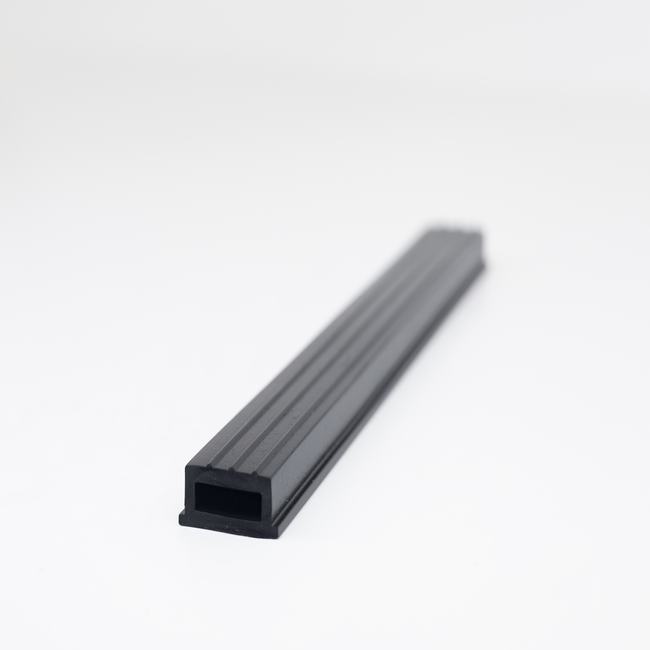

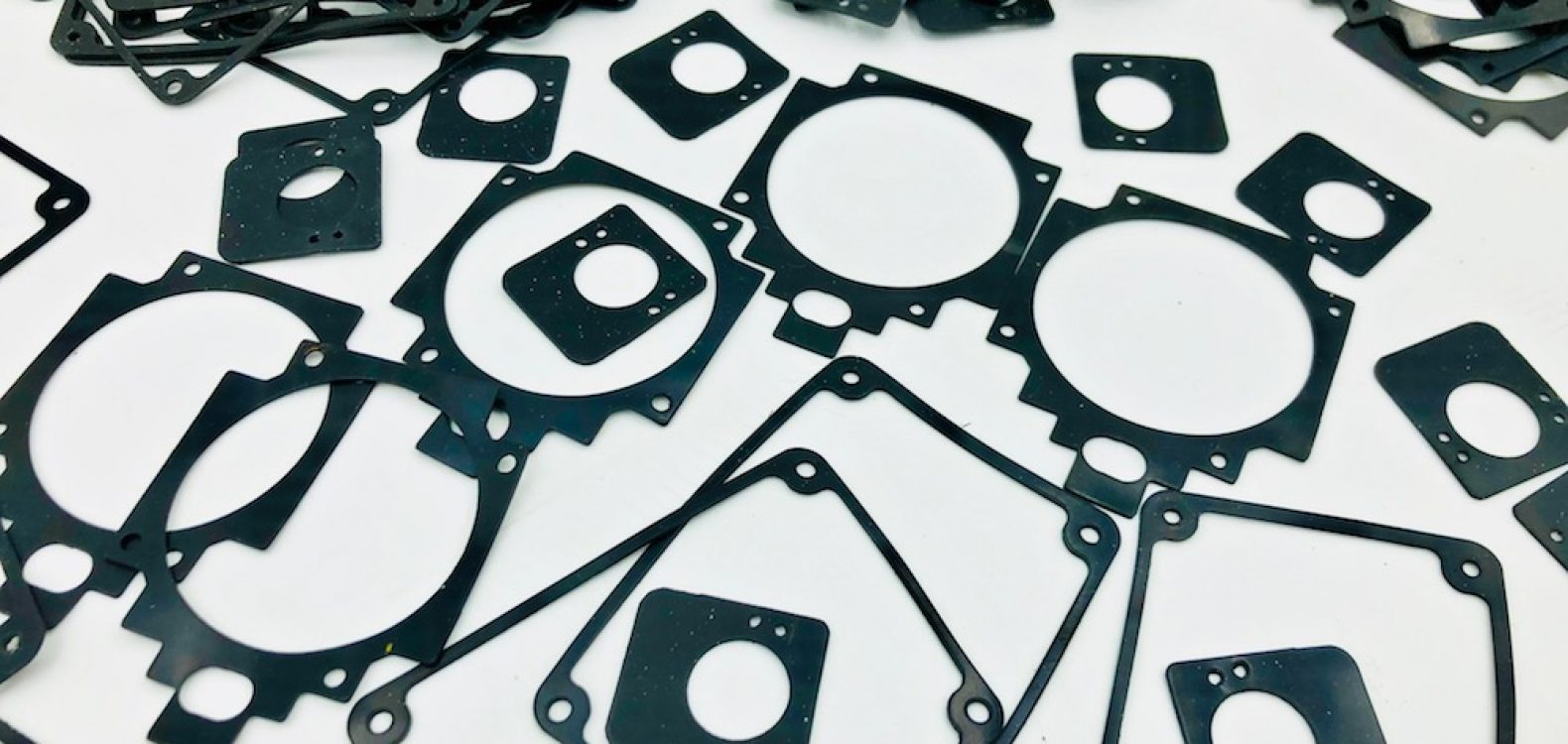

PVC pipe seals, also known as PVC pipe gaskets or PVC pipe joints, are components used to create watertight and airtight seals in PVC (polyvinyl chloride) piping systems. PVC pipes are commonly used in various applications, including plumbing, irrigation, drainage, and industrial systems. PVC pipe seals play a crucial role in preventing leaks and ensuring the efficiency and reliability of these piping systems. Here’s more information about PVC pipe seals:

1. Material Composition:

- PVC: The primary material in PVC pipe seals is PVC itself. PVC is a durable, corrosion-resistant, and chemically inert plastic material, making it suitable for various applications.

2. Functionality:

- Sealing: PVC pipe seals are designed to create a secure and watertight seal at joints and connections in PVC piping systems. They prevent the escape of fluids and the ingress of contaminants.

3. Applications:

- Plumbing: PVC pipes are commonly used in residential and commercial plumbing systems. PVC pipe seals are essential for ensuring leak-free connections in water supply lines, drainpipes, and sewer systems.

- Irrigation: PVC pipes are widely used in agricultural and landscaping irrigation systems. PVC pipe seals are used to prevent water leakage and maintain the efficiency of irrigation networks.

- Industrial: PVC pipes are used in various industrial applications, including chemical processing, wastewater management, and ventilation systems. PVC pipe seals are crucial for maintaining the integrity of these systems.

4. Types of PVC Pipe Seals:

- Socket Seals: These seals are used in socket or solvent-welded joints, where one PVC pipe is inserted into another. Socket seals ensure a secure and leak-proof connection.

- Threaded Seals: Threaded PVC pipe seals are used in threaded connections, such as those found in plumbing fittings. They create a watertight seal when threaded components are screwed together.

- Compression Seals: Compression seals are used in compression fittings, where a nut and ferrule are tightened around the pipe to create a seal.

5. Installation and Maintenance:

- Proper installation of PVC pipe seals is essential to their effectiveness. The seals should be correctly positioned and tightened according to manufacturer guidelines.

- Routine maintenance involves inspecting seals for wear and tear and replacing them as needed to ensure continued leak prevention.

6. Durability:

- PVC pipe seals are known for their durability and resistance to corrosion, making them suitable for use in various environments and with a wide range of fluids.

7. Compliance and Quality Assurance:

- PVC pipe seals, like the pipes themselves, are subject to industry standards and quality control measures to ensure their reliability and performance.

In summary, PVC pipe seals are critical components in PVC piping systems, providing watertight seals at joints and connections. Their durability and resistance to corrosion make them suitable for various applications where leak prevention and fluid containment are essential. Proper installation and maintenance are vital to ensure the long-term reliability of these seals and the overall integrity of the PVC piping system.