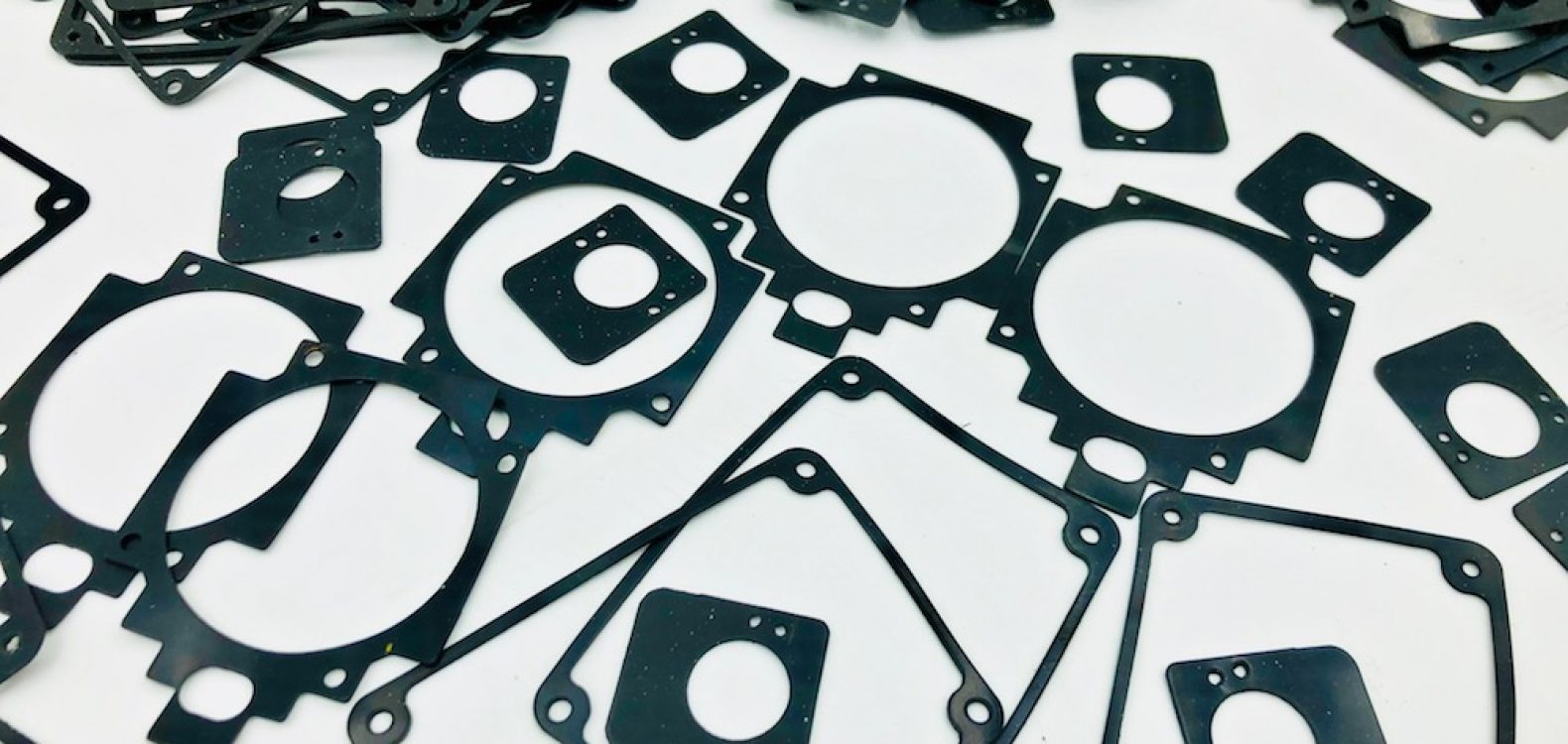

Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are specialized components used in concrete pipe systems to create watertight and secure seals at pipe joints and connections. These seals are essential for maintaining the integrity and functionality of concrete pipes used in various applications, including stormwater drainage, sewage systems, culverts, and more. Here’s more information about concrete pipe seals:

1. Material Composition:

- Rubber or Elastomeric Materials: Concrete pipe seals are typically made of rubber or other elastomeric materials, such as EPDM (ethylene propylene diene monomer) or neoprene. These materials provide flexibility, resilience, and resistance to water and chemicals.

2. Functionality:

- Sealing: The primary function of concrete pipe seals is to create a watertight seal at the joints and connections of concrete pipes. This prevents the leakage of fluids, including water, sewage, or stormwater, and helps maintain the overall efficiency and environmental compliance of the pipe system.

3. Applications:

- Stormwater Management: Concrete pipes with seals are commonly used in stormwater management systems to efficiently transport rainwater away from urban areas, preventing flooding and erosion.

- Sewer Systems: They are crucial components of sanitary sewer systems, ensuring that sewage is transported without leaks or infiltration.

- Culverts: Concrete pipe seals are used in culverts, which are structures that allow water to flow under roads, railways, or other obstructions while maintaining structural integrity and preventing erosion.

4. Types of Concrete Pipe Seals:

- O-Ring Seals: These are circular or toroidal seals that are placed in the groove of the pipe’s socket or spigot end to create a sealing effect when the pipes are joined.

- Profile Gaskets: Profile gaskets have a specific shape that matches the pipe joint profile. They provide a secure and leak-resistant seal when the pipes are connected.

- Lubricated Seals: Some concrete pipe seals come pre-lubricated or require lubrication during installation to facilitate easy assembly and ensure a proper seal.

5. Installation and Maintenance:

- Proper installation is crucial for the effectiveness of concrete pipe seals. The seals should be correctly positioned and securely fitted during pipe installation.

- Regular inspections and maintenance are essential to check for signs of wear, damage, or degradation of the seals. Damaged seals should be replaced promptly to prevent leaks.

6. Durability:

- Concrete pipe seals are designed to withstand the harsh conditions of underground or buried pipe systems, including exposure to water, chemicals, and soil pressure. They have a long service life when properly maintained.

7. Compliance and Quality Assurance:

- Concrete pipe seals must meet industry standards and undergo quality testing to ensure their reliability and performance in various applications.

In summary, concrete pipe seals play a critical role in ensuring the efficiency and reliability of concrete pipe systems used for stormwater management, sewage transport, and culvert applications. They are vital for preventing leaks, maintaining environmental compliance, and preventing structural damage to infrastructure. Proper installation and maintenance are key to their long-term effectiveness.