GRP pipe seals, also known as fiberglass-reinforced plastic (GRP) pipe seals, are specialized components used to provide secure and watertight seals for joints and connections in GRP piping systems. GRP pipes are made from a composite material consisting of glass fibers embedded in a resin matrix. These pipes are commonly used in various industries for transporting fluids, chemicals, and wastewater due to their corrosion resistance and durability. GRP pipe seals play a critical role in ensuring the integrity and reliability of these pipelines. Here’s more information about GRP pipe seals:

1. Material Composition:

- GRP: The primary material in GRP pipe seals is the same as the pipe itself. GRP consists of glass fibers impregnated with a resin matrix, typically epoxy or polyester resin. This combination provides high strength and corrosion resistance.

2. Functionality:

- Sealing: GRP pipe seals are designed to create a secure and leak-proof seal at joints and connections in GRP piping systems. This prevents the escape of fluids and the ingress of contaminants.

3. Applications:

- Industrial Pipelines: GRP pipes are widely used in industrial applications, such as chemical processing plants, wastewater treatment facilities, and power generation plants. GRP pipe seals are essential for maintaining the integrity of these pipelines.

- Municipal Water and Wastewater Systems: Many municipalities use GRP pipes for their water supply and wastewater systems. GRP pipe seals ensure that these systems operate efficiently and without leaks.

- Oil and Gas: In the oil and gas industry, GRP pipes are employed for transporting various fluids. GRP pipe seals are crucial for preventing leaks in these pipelines.

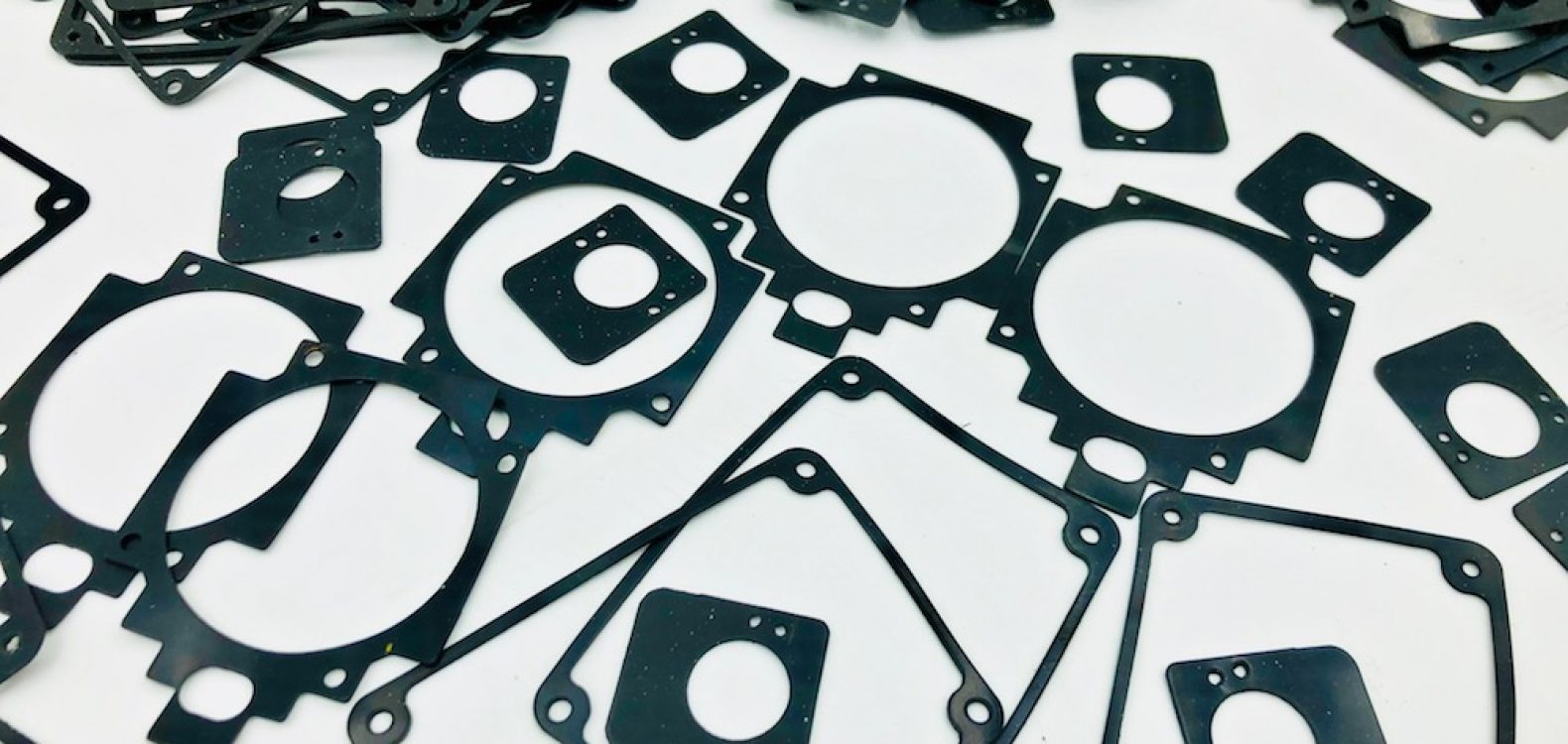

4. Types of GRP Pipe Seals:

- Flange Seals: These seals are used at the flange connections where two pipes are joined. They create a watertight seal between the flanges.

- Coupling Seals: Couplings are used to connect two pipes. Coupling seals ensure a tight connection and prevent leakage.

- End Cap Seals: These seals are used at the ends of pipes to close off the pipeline. They are essential for preventing leaks and protecting the interior of the pipe.

5. Installation and Maintenance:

- Proper installation of GRP pipe seals is crucial to their effectiveness. The seals should be correctly positioned and tightened according to manufacturer guidelines.

- Routine maintenance involves inspecting seals for wear and tear and replacing them as needed to ensure the continued integrity of the pipeline.

6. Durability:

- GRP pipe seals are chosen for their durability and resistance to corrosion, making them suitable for use in harsh industrial environments and corrosive fluids.

7. Compliance and Quality Assurance:

- GRP pipe seals, like the pipes themselves, are subject to industry standards and quality control measures to ensure their reliability and performance.

In summary, GRP pipe seals are essential components in GRP piping systems, providing watertight seals at joints and connections. Their durability and resistance to corrosion make them suitable for a wide range of industrial applications where leak prevention and fluid containment are critical. Proper installation and maintenance are essential to ensure the long-term reliability of these seals and the overall integrity of the pipeline.