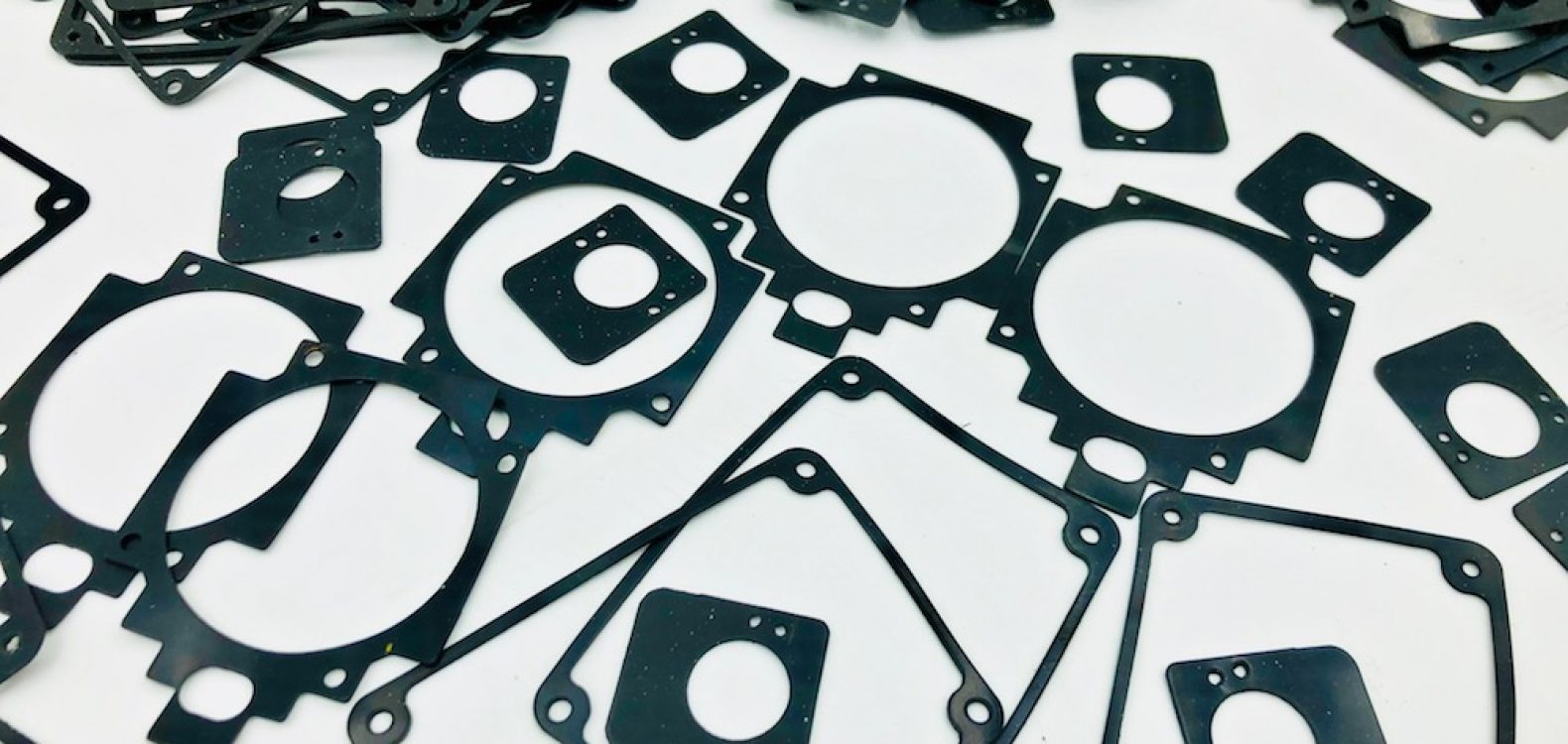

EPDM (ethylene propylene diene monomer) rubber seals, often simply referred to as EPDM seals, are versatile elastomeric components made from EPDM rubber material. EPDM rubber is known for its excellent resistance to weathering, ozone, UV radiation, heat, and a wide range of chemicals, making it a popular choice for seals in various industries and applications. EPDM rubber seals are used to create watertight, airtight, and weather-resistant seals in many different contexts. Here’s more information about EPDM rubber seals:

1. Material Composition:

- EPDM Rubber: EPDM is a synthetic rubber compound composed of ethylene, propylene, and a diene monomer. This combination of materials results in a rubber with exceptional properties, including flexibility, elasticity, and resistance to environmental factors.

2. Key Properties of EPDM Rubber:

- Weather Resistance: EPDM rubber is highly resistant to weathering, ozone, UV radiation, and extreme temperatures. It maintains its performance even when exposed to harsh outdoor conditions for extended periods.

- Chemical Resistance: EPDM rubber exhibits good resistance to various chemicals, acids, and alkalis, making it suitable for use in diverse industrial applications.

- Water Resistance: EPDM rubber is highly impermeable to water, making it an excellent choice for sealing applications where moisture or water ingress needs to be prevented.

3. Common Applications of EPDM Rubber Seals:

- Automotive: EPDM seals are used in the automotive industry for sealing doors, windows, hoods, trunks, and various engine components. They provide weatherproofing and help reduce noise and vibration.

- Construction: EPDM rubber seals are employed in construction applications to create weatherproof seals around windows, doors, roofing systems, and expansion joints.

- Electrical Enclosures: EPDM seals are used to seal electrical enclosures and control panels, protecting internal components from dust, moisture, and environmental factors.

- Industrial Equipment: EPDM rubber seals are found in industrial machinery, equipment, and pipelines to prevent leaks and ensure safe and efficient operations.

- HVAC Systems: EPDM gaskets are used in heating, ventilation, and air conditioning (HVAC) systems to create seals at joints and connections, preventing air or water leakage.

4. Types of EPDM Rubber Seals:

- Extruded Seals: These seals are manufactured by extruding EPDM rubber into specific shapes and profiles, such as O-rings, gaskets, and specialized profiles designed for particular applications.

- Molded Seals: Some EPDM seals are molded into specific shapes, providing precise dimensions and configurations for specific sealing requirements.

5. Installation and Maintenance:

- Proper installation is essential for ensuring the effectiveness of EPDM rubber seals. Seals should be correctly positioned and securely fitted into their intended locations.

- Routine inspection and replacement of seals may be necessary if signs of wear, damage, or degradation are observed.

EPDM rubber seals are valued for their durability, resistance to environmental factors, and versatility in creating reliable seals in various industries. They play a critical role in maintaining the integrity and functionality of systems and structures.